Through a combination of hardware, such as RF devices, and software, such as NetSuite, smaller distributors are gaining a competitive advantage by investing in technology that is designed to streamline their warehouse operations. Australian wholesalers are fast catching up with retail managing their operations more effectively while making informed decisions about shipping, staffing, accounting, demand planning and warehousing.

What is warehouse automation?

Warehouse automation is the use of software and technology to support your warehouse team in their mission to pick, pack and ship your customers orders as quickly and efficiently as possible. This type of technology is designed to streamline the operations of your warehouse, as well as reduce costly errors. Traditionally warehouse automation technology was used by large companies, such as Amazon and Coca-Cola; however, modern cloud ERP is bringing the benefits of what was traditionally large scale software to small and medium-sized wholesale distributors.

What is an automated storage and retrieval system?

Automated storage and retrieval system (ASRS) is the combination of machines and execution software to move product in and out of the storage unit without any human supervision. These machines use sophisticated technology and integrate with a distributors ERP system to minimise human intervention in the picking process. Overhead storage units, by manufacturers such as Hanel, allow distributors to automate their picking process and take advantage of the overhead space in their warehouses.

Ten Benefits of warehouse automation

1.Increasing Speed

There is no way a human can memorise an entire warehouse and beat a fully functional automated system that can instantly identify the location of the items in a particular order. Warehouse automation software is the brain of your warehouse and gives your team the information they need to do their jobs quickly and efficiently, right at their fingertips.

You can also increase the management of an inventory process with warehouse automation. Instead of having people manually record items, RF scanners can short cut the process of collecting information about orders and simplify the administration associated with inbound deliveries and order dispatch.

2. Maximising space

One resource that is not often considered is that of overhead storage. The footprint of your warehouse is finite, and without costly extensions, this cannot be increased. Warehouse automation allows for practice use of overhead space by using machinery and technology to automate the retrieval of inventory items stored at height. In addition to this, depending on the location of your warehouse, more often than not, the cost of extending up, instead of out is usually far less.

How does it maximise space?

Majority warehouse automation systems include robots or other machines that collect products and store them. It means that there is no need to send people to aisles, which could remove the need for wide aisles that accommodate large spaces with a wide turning radius. Automated warehouses have unique movable shelves that can move goods around on a pallet. However, they tend to take up more space than a pallet, whilst a robot needs less room for maneuvering. This automation logic means that you can install products with smaller aisles, which can create more space for storage.

3. Decreasing Costs

Whilst there is a reasonable investment associated with implementing warehouse automation software and hardware, the benefits of reduced costs in labour, order errors and fulfilment velocity far outweighs the cost, which leads to rapid ROI for a wholesaler.

4. Low injury risk

Warehouse automation technology also helps minimise the risk of injury to warehouse workers, by using machines to carry out dangerous tasks. One of the main drivers of the IOT and Smart Factory initiatives is that of safety.

5. Accuracy

Accuracy in the warehouse business is no doubt necessary; it helps reduce errors in dispatch, which result in returns and extra administration. Wholesalers who use ERP technology and warehouse automation software see drastically lower errors in picking, packing and shipping and report higher levels of customer satisfaction and repeat business.

6. Increased efficiency

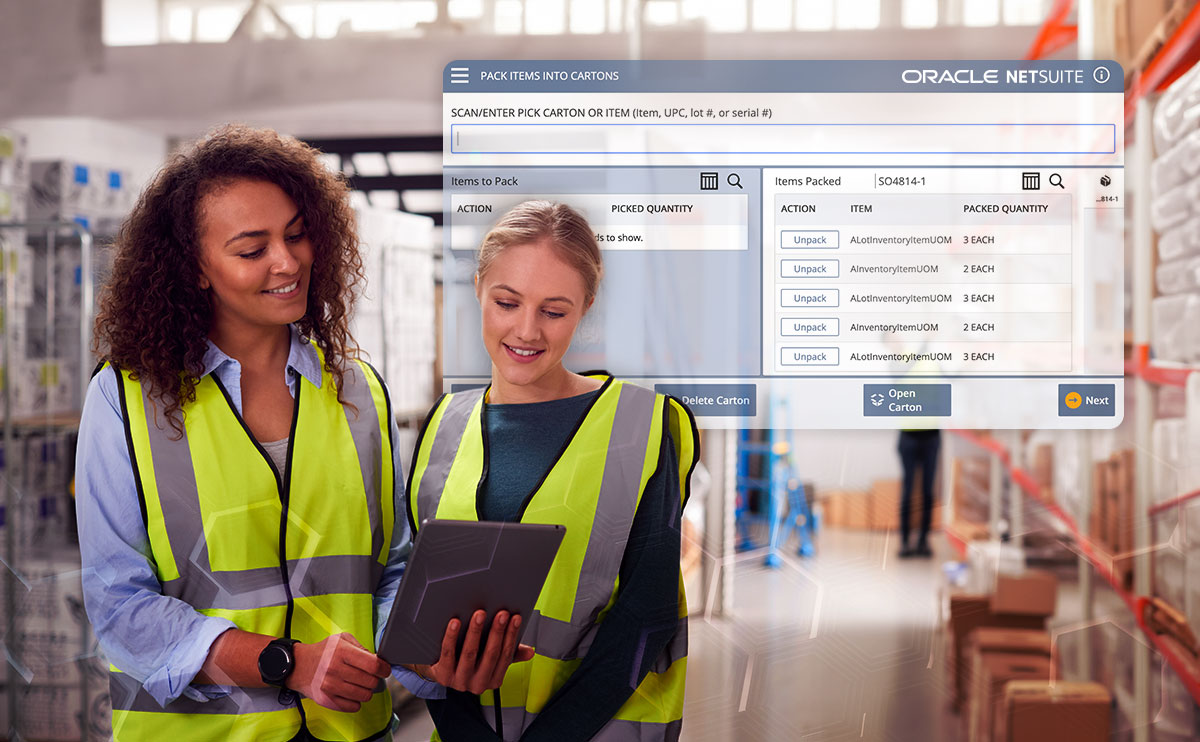

Automated tools help strengthen the entire process, from picking and receiving items through assembly lines and out to distribution. Wholesale Distribution Software vendors, such as NetSuite design their packages to meet the demands of every warehouse, which will keep products organised and send out automated alerts.

7. E-commerce

Automated warehousing can provide benefits like space saving, reduced building costs, improve productivity, needing fewer people, saving money and reducing operation cost. When this is paired with integrated e-commerce platforms, a wholesaler can expand their sales channels whilst still maintaining control over their warehouse.

8. Accurate analytics

Automating a warehouse is a short-term investment on time and labour, however, the additional data being captured by the system gives wholesalers access to better analytics and information about their business which empowers strategic decision making.

This knowledge helps in taking your business to the next level as you can share real-time data to managers, gain insights into your business and identify key areas of improvement.

9. Save time and money

With a warehouse automation system and ERP software being able to keep track of goods and supplies is more manageable, as the system is largely taking care of what people had to track manually. This strategy helps reduce the number of employees required to maintain your current level of operation and allow you to grow without having to put more people on to cope with the additional workload.

10. Better Inventory Control

Features in ERP technology, such as demand planning help a wholesale distributor by providing intelligent suggestions as to what to order, by using the data in the system to calculate expected supply and demand plans.

Cloud-Based Warehouse Software

A cloud-based warehouse management system (WMS), such as NetSuite makes sure all warehousing operations are executed smoothly. NetSuite tracks data in real-time, which can help managers get instant notification of inefficiencies or errors in the business and correct these to ensure continual improvement of operational efficiency. The advantage of the cloud is also the ability to connect your ERP other automation technologies such as robots, conveyors, overhead storage and other machines through API technology that interacts with the Internet of Things.

Gigant Chinese retail Alibaba, ramped up robotic labour in 2017 in one of its warehouses, cutting down the workforce by 70%. Robotics will continue to have a significant impact on the supply chain. Choosing a platform that eases automation will enable wholesalers to adapt to future trends, move quicker than the competition, manage their operations better and target strategic growth with informed decisions.

Need a specialist’s free advice?

Feel free to call an expert in Wholesale and Distribution Enterprise Resource Planning Systems today. Find out how cloud-based technology can support your business growth.